Researchers on the Massachusetts Institute of Know-how (MIT) have made a groundbreaking development in 3D printing lively electronics with out the necessity for conventional semiconductor supplies. This breakthrough entails creating 3D-printed logic gates, basic elements utilized in processing duties inside digital units. As an alternative of counting on typical manufacturing processes, these logic gates had been produced utilizing normal 3D printing strategies and a biodegradable polymer. This step brings the idea of absolutely 3D-printed electronics nearer to actuality, providing thrilling prospects for accessible and decentralised electronics manufacturing.

Semiconductor-Free Logic Gates

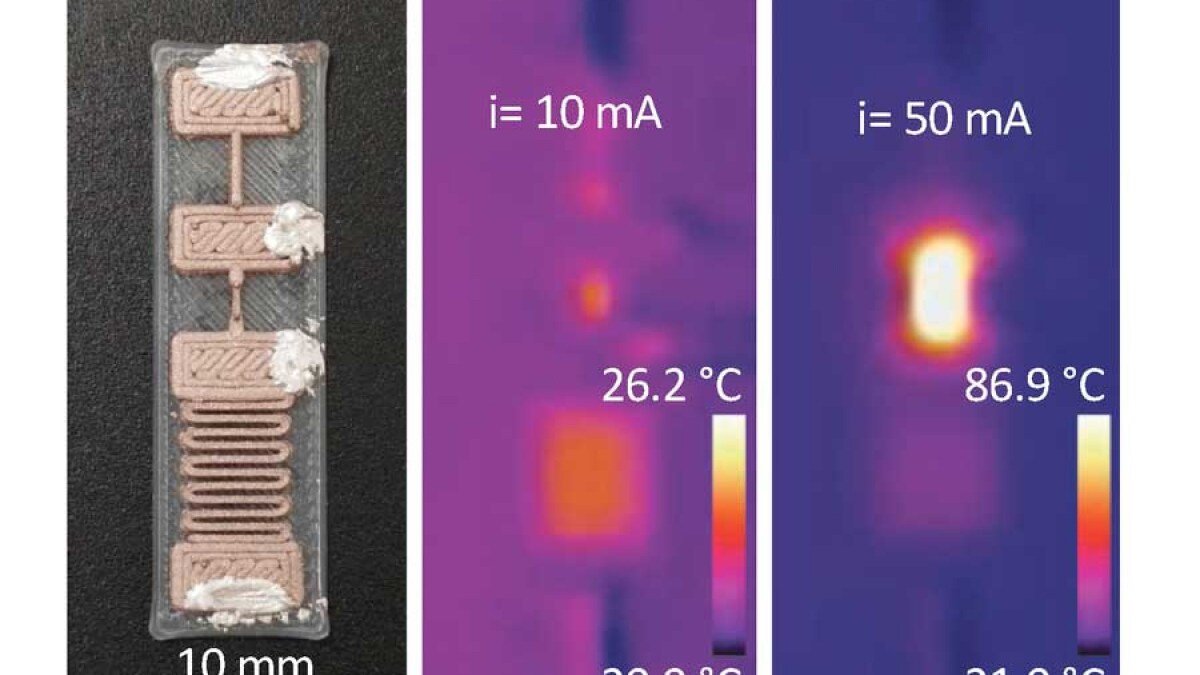

MIT’s analysis staff, led by Luis Fernando Velásquez-García from the Microsystems Technology Laboratories, has developed logic gates utilizing a copper-doped polymer, avoiding the usage of conventional semiconductors like silicon. These gates carry out fundamental switching operations, much like how silicon-based transistors perform in on a regular basis electronics. Whereas these 3D-printed elements usually are not but on par with silicon transistors when it comes to efficiency, they are often successfully used for much less advanced operations, corresponding to controlling the pace of a motor.

The innovation lies within the capacity to 3D print these units utilizing cheap, eco-friendly supplies, probably permitting electronics to be manufactured in a extra sustainable and reasonably priced method. The thought is to democratise manufacturing, enabling people, companies, and small labs to print their very own units.

The Way forward for Totally Printed Electronics

Regardless of the present limitations, corresponding to the shortcoming to miniaturise these elements to the nanoscale stage of conventional transistors, the potential of 3D-printed logic gates is immense. MIT’s analysis staff is already exploring additional developments to create extra advanced circuits and ultimately absolutely useful 3D-printed units.

This expertise, if perfected, may revolutionise the best way digital units are manufactured, making it attainable to print lively units with out the necessity for costly, large-scale services. The implications for industries starting from shopper electronics to healthcare and past might be huge, as this innovation brings down the associated fee and complexity of system manufacturing.